Contoh yang terjadi di Indonesia menunjukkan betapa pentingnya pariwisata dalam mengurangi kemiskinan. Hal ini terutama terlihat pada masa epidemi, ketika...

Jakarta (dpa) - Kepastian yang mengerikan setelah berjam-jam ketakutan: tragedi pesawat di lepas pulau Jawa mungkin telah merenggut nyawa 62...

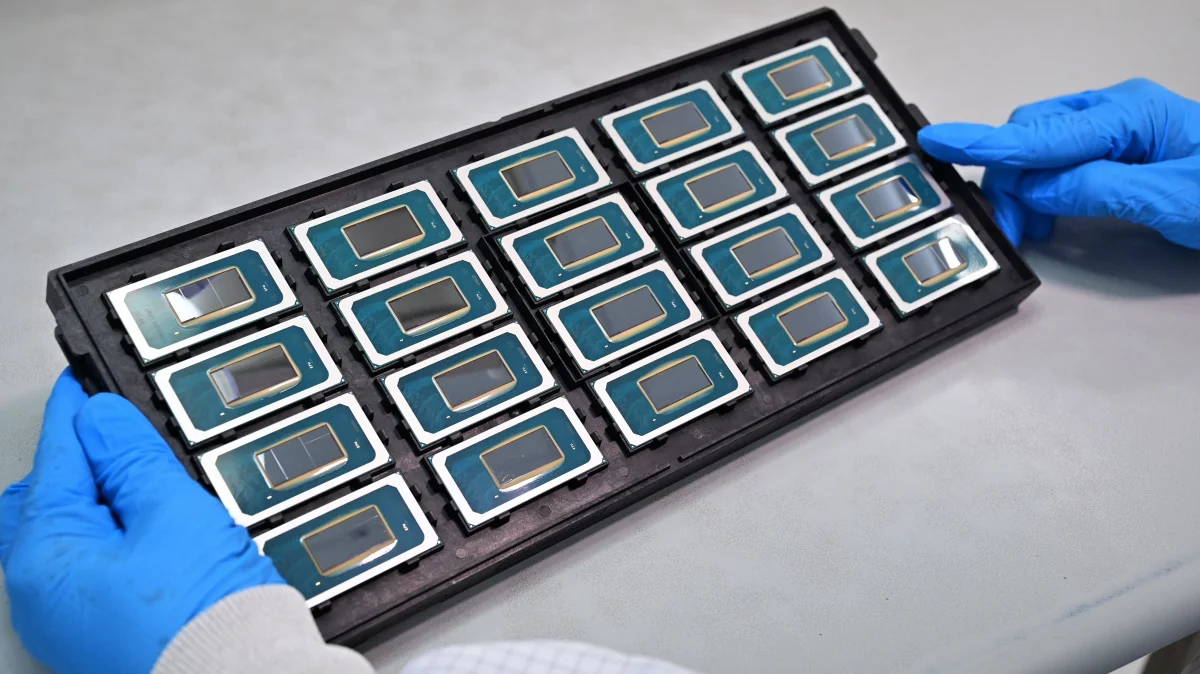

Baik AMD dan Intel tampaknya sedang mengerjakan prosesor terintegrasi dengan unit grafis yang sangat kuat. Mereka dapat ditempatkan di PC...

Presiden Ukraina Volodymyr Zelensky (Evgeniy Maloletka/AP/dpa/Evgeniy Maloletka) Dia mengatakan dalam pidato video malamnya bahwa masalah tersebut menyangkut wilayah yang terletak...

Beberapa minggu sebelum pembukaan: Indonesia berganti kepala ibu kota baru Istana Kepresidenan Masa Depan di Nusantara © AFP Presiden Indonesia...

Harga makanan Kini minyak sawit juga: Indonesia semakin meningkatkan tekanan harga Para pekerja memuat buah kelapa sawit ke sebuah perkebunan...

Karena BIOS Platform Klien Dell berisi kunci enkripsi keras, penyerang dapat menyusupi seluruh sistem. Menurut produsen PC, berbagai model laptop...

Rumahpanoramakondisi: 29 Agustus 2024, 06:13dari: Michel GudatDia menekanTerbagiSatu dekade kemudian: Kemajuan dalam kasus hilangnya “MH-370” secara misterius? Seorang ilmuwan mungkin...

Ribuan masyarakat di Indonesia memprotes rencana pemerintah mereka. Pemerintah berupaya untuk membatalkan keputusan Mahkamah Konstitusi yang membuka pemilu bagi partai-partai...

Panduan pendidikan iklim baru ini bertujuan untuk mengajarkan gaya hidup berkelanjutan kepada siswa Indonesia. Perwakilan Gereja Katolik di negara tersebut,...